PIGMENT TOKYO carries TranTixxii® Color Titanium Panels.

The titanium panels are known for their quality and a wide variety of colors and textures. They are used for architecture such as museums, stadiums, temples, and shrines in Japan and other countries.

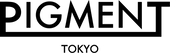

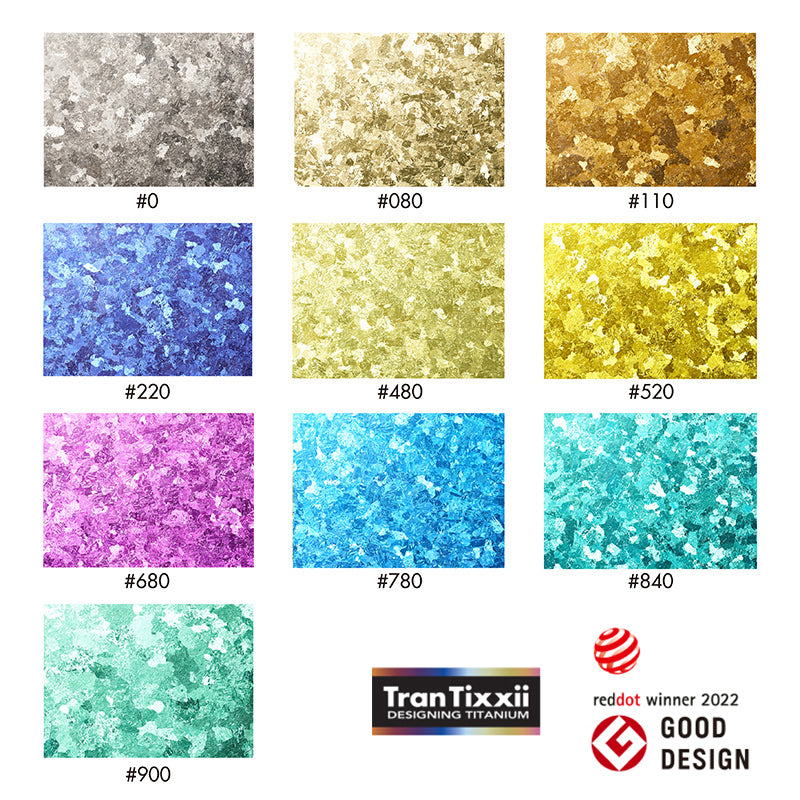

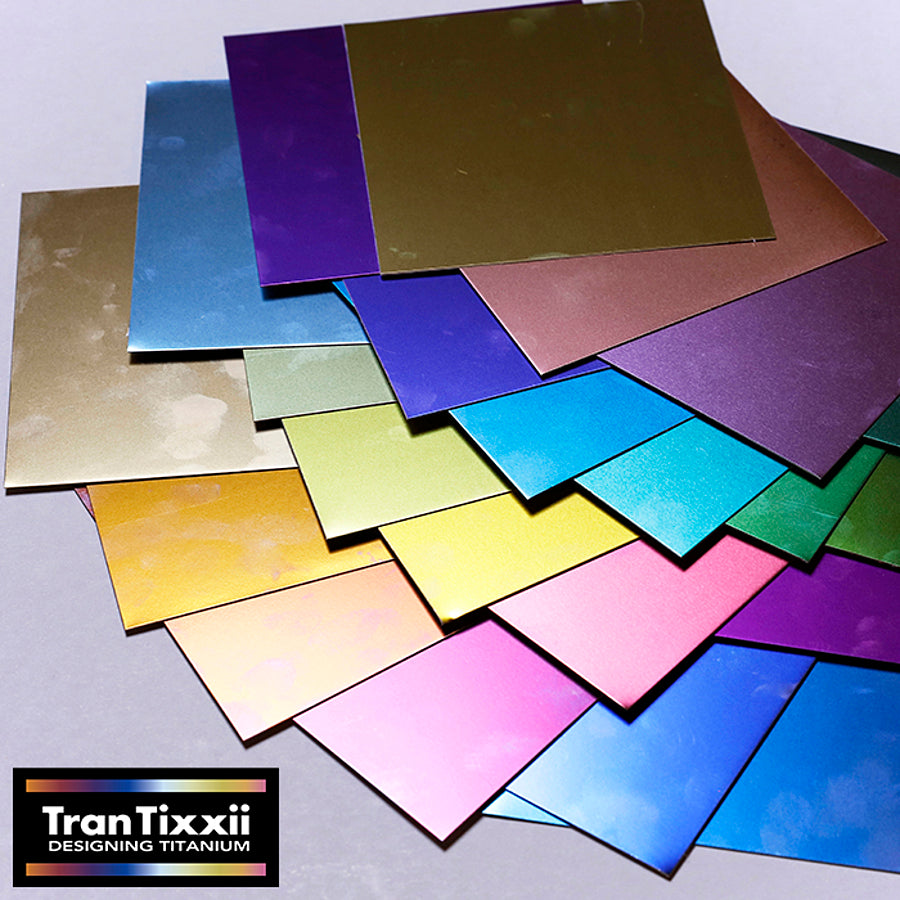

In PIGMENT TOKYO, a variety of colors and textures are available, including SD3 with a smooth and shiny surface, ND20 with a slightly rough and matte surface, blasted titanium panels with a surface treatment that forms small bumps on the material surface and Hyper β with a rough texture and a crystalline pattern on the surface.

Among the above, the most basic SD3 and ND20 series comes in 23 colors each.

However, pigments are not used in these panels since they are not painted.

If that’s the case, how can these colors appear without using any colorant?

The answer is that these colors are created by adjusting the thickness of thin-coated layers called oxide film.

First of all, the color can be observed through the light reflection. For instance, when we are in a completely dark room, we cannot see colors or even recognize the shapes of objects. It is because they are not reflecting any light. On the other hand, we can see the colors on a smartphone's screen even in a dark room. In this situation, the screen is glowing, and we can recognize the "colors" on it.

In other words, humans cannot perceive colors unless there is a reflection or emission of light from a light source.

There are two different ways to receive colors through our eyes: the three primary colors of pigment and the three primary colors of light. The three primary colors of pigment are also known as the primary subtractive colors which are cyan, magenta and yellow.

Equal mixing of these three primary colors produces black thus, it is referred to as CMYK, and this theory is applied to printing. Of course, paint also has this property and black paint can be produced by mixing the three primary colors of paint.

The three primary colors of light are red, green, and blue which are also called additive primaries. When these three color lights are superimposed, it becomes white light and this is how the color of the displays and screens is rendered. This method is also known as RBG.

The images below illustrate what I just explained. On the right are the "three primary colors of pigment" and the "three primary colors of light”. However, when actually mixing the paints, even with equal amounts of cyan, magenta, and yellow paints do not produce perfect black. The same for printing, black ink is used in addition to these three primary colors.

The colors of TranTixxii® introduced here are also called interference colors, and this is the reason why rainbows appear after rain, the sky appears blue and soap bubbles have rainbow colors. The thickness of the coating films used for TranTixxii® is at most 0.15μm. For reference, 1μm is 0.001mm, so you can imagine how thin the coating films are.

Correlation between film thickness and interference color (from the official TranTixxii® website)

Now, you may ask how this oxide film is produced.

I had an opportunity to ask about the mechanism to Mr. Naoaki Takimi from Shinwa Mekki Industry Company. The company has a factory in Joetsu City, Niigata Prefecture, and in addition to plating industrial products, they also develop colors of titanium, including TranTixxii®.

Mr. Takimi from Shinwa Mekki Industry Co.

The company also processes plating of gas meters which are commonly seen in Japan. Some of you may have already been familiar with the company's products.

The oxide film of colored titanium is produced by a process called "anodic oxidation treatment.” When voltage is applied to titanium immersed in a certain chemical liquid, hydrogen is generated from the cathode (negative) and oxygen from the anode (positive), and then the oxygen and titanium combine to form a titanium oxide film on the surface.

Diagram of the anodic oxidation process. ( cited from public relations material of Shinwa Mekki Industry Co.)

This process does not change the physical properties or durability of the material when compared to other coloring methods and there is no risk of peeling. The coating film protects the material, so the texture of the metal itself can be maintained stably.

At first glance, the color application looks very simple, but since the color changes depending on the time the electrode runs, professional skills are required to obtain consistent coloration in mass production.

Although the color chart shows the theory of mixing the three primary colors is called a color wheel, how the colors keep appearing in order of color wheel gradation here is exactly the circulation of colors.

Mr. Takimi explains how the color changes depending on the time the voltage is applied. The company offers 60 various color patterns.

Let's see how titanium actually develops color.

① First step is making the liquid for the anodic oxidation process.

② Next is preparing a titanium sheet treated with a special process.

This time, we had a sheet engraved with the logo of PIGMENT TOKYO on it. This kind of laser treatment can be applied because it is made of titanium. It comes in dull silver before developing any colors.

③ When voltage is applied to the titanium sheet soaked in the solution, the color started changing to a light brownish color.

④ Let the titanium sheet keeps on contacting under the same voltage and the color later has changed to purple. It is as if we are watching a real-time color wheel test.

⑤ We can also control the time of voltage applied to the material by taking the titanium out of the solution to create a color gradation.

⑥ Here is the result. The gradation is so beautiful as if the metal was heated by a burner. Later, a final treatment will be done by the company to complete the piece.

For the demonstration today, we applied the color-changing process to the sake cups and rulers.

The silky texture and modern color are beautiful and unique from other metals. Titanium is lightweight, strong, and deformation-resistant, making it suitable not only for tableware but also for daily necessities.

The "sake cups" and "fish-shaped rulers" from the “iroiro" series produced by the company.

TranTixxii® is a world-class material from Joetsu City, Niigata Prefecture. Its potential is not limited to industrial products but also has great potential as art materials. PIGMENT TOKYO carries SD3 and ND20 titanium panels in smaller sizes for sample use.

Kei Saito, an art materials expert at PIGMENT TOKYO, performing a demonstration with TranTixxii® in 2020.

Kei Saito, an art materials expert at PIGMENT TOKYO, performing a demonstration with TranTixxii® in 2020.

It can be painted with acrylic, oil paints or applied metal leaf on it, thus, it has the potential to expand your creativity with your new ideas. We hope you will enjoy experimenting with this new material proudly made in Japan.

Company Information

SHINWA MEKKI CO.

Location: 1631 Tsuchihashi, Joetsu City, Niigata, 943-0821, Japan

Phone: 025-524-5426

Website:https://www.shinwa-mekki.jp/

iroiro :https://iroiro22.jp/

TranTixxii® Official Website