At the PIGMENT TOKYO online store, "Color Titanium Panel" is now available as a painting substrate using TranTixxii®, a designing titanium plate developed by Nippon Steel Corporation.

https://pigment.tokyo/en/collections/color-titanium-panels/products/4557

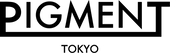

There are two types of surface textures, the image shown above is the type SD3 with a smooth surface, and the type ND20 has a rough texture. As I mentioned in my previous article, we gave a demonstration to create artworks using TranTixxii® during the press conference.

The first performer is Kei Saito, he is a painter and also works as an art materials expert at PIGMENT TOKYO. He used masking tape to cover some areas and painted on top of it, therefore it willleave the original titanium surface to stand out with the metallic luster from the painting. It was great to see his technique of making original paints by using our pigments.

The second artist was Mitsuyasu Nemoto, a calligrapher. He created a conceptual work using the coordinate axis of Google Map as its theme. The deep lusty color of TranTixxii®glowed with beauty as a substance that enhanced the minimal expression.

Last but not least, Shin-rei who also is a calligrapher. She used a combination of AQYLA, a water-based alkyd resin paint, and acrylic paints to draw the word "感, Kan".

* Both AQYLA and acrylic paints are available in PIGMENT TOKYO.

By using those paints, she expressed color blending and "blurring" with her talented brush handling skill without repelling the color.

After the press conference, we interviewed Kiyonori Tokuno, a leading expert in titanium designing plates who has played a central role in the development of TranTixxii®

since its early days. (Interviewed in February, 2020)

-TranTixxii® sure is an interesting product!

There are several core technologies in the TranTixxii production. After years of developing unique technologies, we have established a distinctive worldwide brand that pursues "beauty" in titanium.

Not to mention, we have been collecting customers' feedback and encouragement, so we could adapt those voices into our products. We clarified all the problems and solved technical limitations when we faced issues. After dozens of prototypes and fine-tuning, we have successfully launched TranTixxii.

As an engineer, I always keep this concept in my mind, “I want tocreate something new, something that has never existed before, using titanium as an industrial product.”. However, shaping the idea of a new product takes time and requires a lot of experimentation and testing.

Especially, it takes a lot of time to clarify the production mechanism and to be able to produce a stable product with reproducibility rather than a one-time success.

With all my strength and all my heart,I’ve dedicated to technological development of the TranTixxii Titanium. I still remember vividly when establishing each technology.

Especially, as the important & core technology for the Titanium brand, I have strong attachment to 3 technology.

In the beginning, we startedthe TranTixxii brand by establishing mass production technology for the dull finish (ND20), one of the basic textures.

Secondly, we established the world's first & Only1 “Stable Color”technology which form the foundation of the long life beauty of the TranTixxii Titanium,(overcoming the unique weakness of Titanium Discloration).

Thirdly,Ion platingis another surface finish technique that can deliver a surface that is glossier than “gold” and with superior durability.

Kiyonori Tokuno, answering our interview in an enthusiastic tone.

-Why did you first become interested in titanium?

When I was in university, I happened to come across titanium. Back in the '70s, designing titanium was only used for eyeglass frames, not yet used for golf clubs, watches or even cups like today, and it was just starting to be considered for use in construction.

As I learned more about it in the laboratory, I gradually became interested in titanium and became fascinated with it. Perhaps, at that moment, I intuitively felt that the research of this material suited my personality.

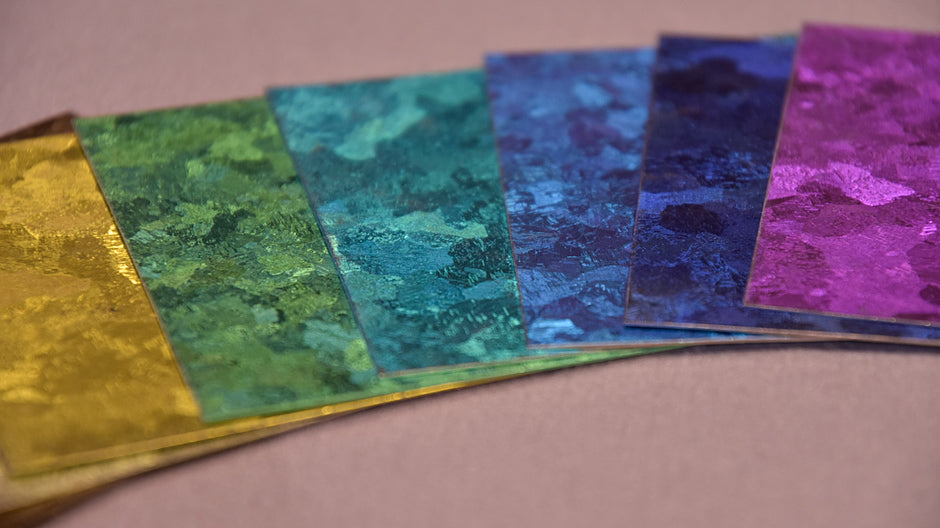

Product samples with a wide variety of textures. All made from the same material.

-Is that when you saw the potential of titanium?

At the time, it was the dawn of titanium, less than 30 years since its mass production started. While many previous studies on other metals existed, including practical aspects, there was not much information on titanium. I took the situation optimistically because there was room for developing the material, and it could be a chance to test my capability as a pioneer.

I thought it was probably a perfect opportunity to create something completely new that had never appeared in the world. I had heard that "titanium is resistant to seawater and does not rust semi-permanently" since I was a student.

However, I honestly did not expect that titanium would be used in such a wide variety of products since that time, including designing titanium, which I was involved in its development.

Experimental samples that have been created through trial and error.

-What were your thoughts when you were developing these products?

As a basic premise, I had a strong sense of trust in the properties of titanium, which is "semi-permanently rustproof.” If it were a metal that would soon decay and be consumed, I might not have been so involved in trying to accumulate new value. Compared to ordinary metals, titanium may be more like a precious metal in terms of maintaining its value. The value of the "beauty" of designing titanium is not transitory, it is semi-permanent and can be passed on to the next generation. I think that I have been able to achieve this level of passion because the efforts I have made little by little have been able to accumulate in this way. The experimental samples of titanium designs shown here can theoretically transcend time by hundreds or thousands of years. I believe that titanium is a metal that is worth working hard for.

When I first joined the company, my boss used to give me challenges such as, "How can we make new titanium with excellent workability and corrosion resistance?" and "How can we produce it efficiently?" However, I always focused on the question, "What kind of new products and a new value can we provide to our customers?"

I was very passionate about achieving the needs of customers and creating new value through titanium, metal in its infancy.

Nippon Steel Corporation has always been very open-minded for diverse members with different potentials, where each employee can make the most of their individuality. It is very appealing to me that there is an environment where I can think about how I can utilize my skills to develop my business with my colleagues.

In this environment, with the support of my mentors and colleagues, I have been able to work relatively openly from a young age, faithfully following my ideas.

-What were some of the challenges you faced in the development process?

In earlier days, it was hard to find the right answer to the question, " what should we do to make a stable product as a material."

I believe that we have achieved this point today because our company allowed us to continue to accumulate the results of our basic research and application methods through a long period of trials and experiments.

Regarding the designing titanium that we developed, a breakthrough came when a group of technologies that we completed after such a large amount of research was adopted by an architect for a large-scale exterior design.

Like I said at the beginning of this interview, "I wanted to create something new that has never existed before."

However, to develop specific technologies, I have always kept my commitment and continued to push myself hard to "make things common that were not common ten years before."

-On the other hand, are there any moments that you feel joy related to the productions?

Of course, we do! Especially when we successfully produce some fantastic products, I feel an accomplishment like “We made it!” I can say that even for now, I still feel this excitement every time I develop new technology.

However, without persistent trial and error, analysis and consideration of experimental results, and accumulation of research results, which I call it as training, these technological developments will not lead to results because they cannot be applied when faced with a new reality. However, the training process is so rigorous that you have to be prepared to devote your life to your work. There are often gaps between what we on the technology development side envision and the customer needs. Without having applications for various situations, we just set limits to ourselves from the beginning and run away.

At this point, I believe that the observational and application skills cultivated through the training, which seemed like a waste of time, make it possible to reconcile the gaps. In my opinion, this is essential for creating something new.

-Can you tell us about your future plans?

I still have many ideas that I'm working on in my head. I am always looking for opportunities to create "what I truly want to create," based on the needs and timing of the world.

Titanium, which uses cutting-edge technology to create completely new value, is also reproducible and can be mass-produced to deliver value to a wide range of people. It is my dream and ambition to develop such a technology and business that will surprise the world. I still have a lot of things to do, but I would like young members to work hard and create new products from a different point of view than mine.

New versions of designing titanium are also constantly being created through a process of trial and error.

I am very encouraged to be associated with PIGMENT TOKYO and to have the chance to support new aesthetic expressions and create new values.

The first phase of the collaboration with TranTixxii® was to develop the basic menu with the titanium that I have been involved in developing, but I am looking forward to releasing the most advanced menu, which is still in the experimental stage, in a completely new way that will add color to the world.

I'm afraid to say this by myself, but the experimental samples here are undoubtedly the first of their kind in the world and have never existed before, so PIGMENT TOKYO is at the forefront of the world.

You can't afford NOT to take advantage of this great opportunity. *laughs*

When I saw the performance of the three artists, I was completely touched, just as I saw artworks in person in the museums.

I am deeply grateful for the opportunity to collaborate with PIGMENT TOKYO, which has such talented people as its staff and partners.

As a person who has devoted all my life to titanium, I wanted to bow down to the power of Mitsuyasu Nemoto's work which expressed his calligraphy skill with the concept based on the historical background of titanium.

Nearly 20 years ago, an incident made me realize that I was just an engineer and I learned that I should not use my aesthetic sense as a standard for development. I realized that what moves people's hearts is the power and skills cultivated through determination and effort in the field.

As you can see, Titanium still has a lot of potential for development. My next goal is to create a place where I can pass on this charm, potential and pleasure to my younger colleagues and educate engineers who can succeed me.

I have been able to pursue my research and challenge the development of titanium because of the free and open-minded environment that I inherited from my colleagues and the foundation of a vast accumulation of technologies and knowledge.

Nippon Steel Corporation Head Office

Marunouchi Park Building, 6-1, Marunouchi 2-chome, Chiyoda-ku, Tokyo, Japan

TEL: 03-6867-4111 / FAX: 03-6867-5607

https://www.nipponsteel.com/en/index.html

Website for the TranTixxii® brand

https://www.nipponsteel.com/en/product/trantixxii/

Translated by Atsumi Okano,Nelson Hor Ee Herng

PIGMENT TOKYO Art Materials Expert