Do you know how the oil paints found in art supply stores are manufactured?

You may think all the processes, including the filling work are done by the machine. Surprisingly, some of the processes are done by hand.

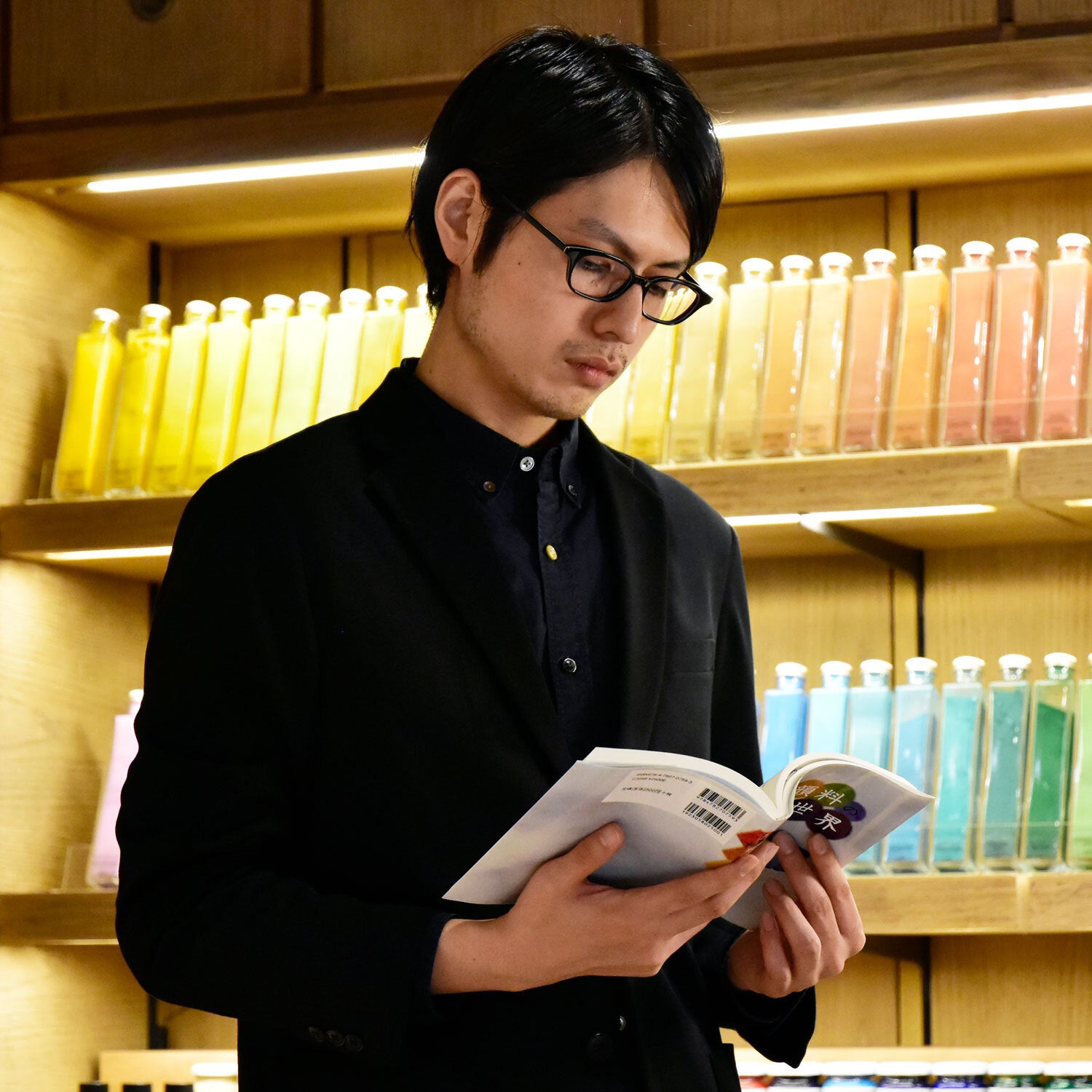

Today, we visited the head office of Japan's paint manufacturer KUSAKABE in Saitama. After observing the manufacturing scene of oil paints with Mr. Iwasaki, the manager of the technology development division, we had a chance to experience making original oil paint. In this article, we will show you the production process.

1. Mixing pigment and medium

Paints cannot be produced without pigments and medium.

This time, we will be mixing with oil-based medium since we are making oil paint.

However, for those who have used oil paints before might realize that it is difficult to adjust the texture by only mixing with Linseed oil and pigment, because the viscosity of paints is insufficient.

Which is the reason why we need Stearic acid. Stearic acid has a moderate texture. Also, it has a quality of helping the dispersion of pigments so it is an essential when you make an oil paint. In addition, Stearic acid contains in our body because it is a main fat saturated fatty acid in animal and vegetable acid.

Therefore, the oil paints with moderate texture has been produced by mixing pigments with the medium of Stearic acid and Linseed oil.

2. Knead paints with roller

Since the medium and Pigments cannot be mixed evenly only with a knife, we need to continue the kneading process. In the old days, when tube paints went on the market, using marble slabs and kneading rods for hours and hours made oil paints. Therefore, three rollers are used to knead the oil paints because it is difficult to produce on a large scale by hand.

These three rollers rotate in alternate directions and adjust kneading evenly by fixing the space subtly.

Comparing the paints before and after putting in a roller, they are strikingly obvious.

We can see that the color is good, matte, and the air bubble is reduced.

For making Ultramarine this time, the process of kneading with rollers needs to be repeated 4 times.

3.Filling in the tube.

When we make oil paint tube in the factory, usually the filling machine will be used. This time, since we are making only one oil paint, let's do the process by hand.

Firstly, wrap the tracing paper around the tube, and fold inside.

Then, put paint inside and press it with palette knife, we are ready to finish.

4.Cleaning

Lastly, let's clean up three rollers.

Firstly, use the calcium carbonate which is also used as an extender pigment to remove the oil on roller roughly.

After that, take off the upper side of the instrument and clean them with oil (petroleum). This is the important part of the machine to prevent paints from spreading.

Finally, let's move on to clean the rollers. Surprisingly, this process can be done without stopping the machine.

Placing the hand on the opposite direction from the rotation to prevent being caught by the machine, and keep cleaning carefully and politely.

We can understand that the oil paints we use in our daily life are manufactured through a variety of processes.

For the event information, please refer to KUSAKABE official website.

https://www.kusakabe-enogu.co.jp/english/

Corporate Data

KUSAKABE

Head office & factory

3-3-8, Hizaori-cho, Asaka city, Saitama

Tel: +81-48-465-6661